Wow, it has been over two years since I posted anything. I never forgot about you, dear readers, and some of you have kindly contacted me from time to time to see if I was OK. I appreciated the concern and I'm fine.

Lots of stuff has happened in my life. I moved, which I did blog about a couple of times. I had yet more joint replacement surgery (everything working quite well). I had covid this summer, but after taking advantage of the shots as they became available it was no worse than a bad bout of flu. And then there were the life altering events, both good and bad. Or both at the same time. You know, the usual.

But you're not here for that, and don't worry, I have not suddenly become that person that spills their personal life on the internet. I know you, dear readers. YOU'RE HERE FOR THE SEWING MACHINES.

And one of the many reasons I haven't been blogging is that I wasn't doing anything with sewing machines (except sewing with them) and therefore had nothing to say. Another reason was that I couldn't see the screen on my laptop, but I finally got some glasses just right for that one thing.

Hence the original working title of this post:

I can see clearly now. And sit in my recliner and blog after a long day wrestling with a vintage sewing machine. Because sewing machines have come back into my life.

So. I joined a church in the denomination in which I was raised after an absence of over 50 years. Long and no doubt fascinating story which I am not going to tell you (see above). At the end of my initial meeting with the minister I joking said that I was going to be looking for some way to be useful but that my only skill was repairing sewing machines, and had he ever thought about a sewing machine ministry?

That was meant to be a laugh line. Obviously. But he said they had just had an email the previous week from someone who wanted to donate a machine for the church to use.

Surprisingly the church had never perceived any need for a sewing machine. But one thing led to another and I now have three sewing machines that I have assessed, have either repaired or failed to repair, and am free to dispose of as I see fit. A Necchi BU with a bad motor, an absolutely lovely Elna SU, and a Brother VX-808. And my plan has been to fix them, sell them, and donate the money to a particular church program that feeds people in need.

I'll tell you more about the Necchi and the Elna in future posts. See, I do plan to resurrect this blog! But today you will hear the sad story of the Brother VX-808.

I would call it late-vintage and I would never have bought it and will never sell it. It's clearly from a time when manufacturers were just beginning to cut costs. It weighs the usual 40-some pounds of good-vintage. The housing is all plastic, but that isn't really a problem. It is ALMOST all metal inside, and this is the really sad part of the story. For an extra dollar or two of production costs (and I made that up, I really have no idea) this could have been an excellent machine with decades more life left in it.

But no. There is a nylon gear with hairline cracks. It hasn't failed--yet--but I just don't sell machines with known problems. And the really sad part is that the only other non-metal is the plastic in the tensioner (photo above). The tension is not quite correct and it is impossible to change it. The tension knob turns, but it does not grip anything, just spins around. I have had it in and out of the machine many times tinkering and trying to get it at least to produce a better tension.

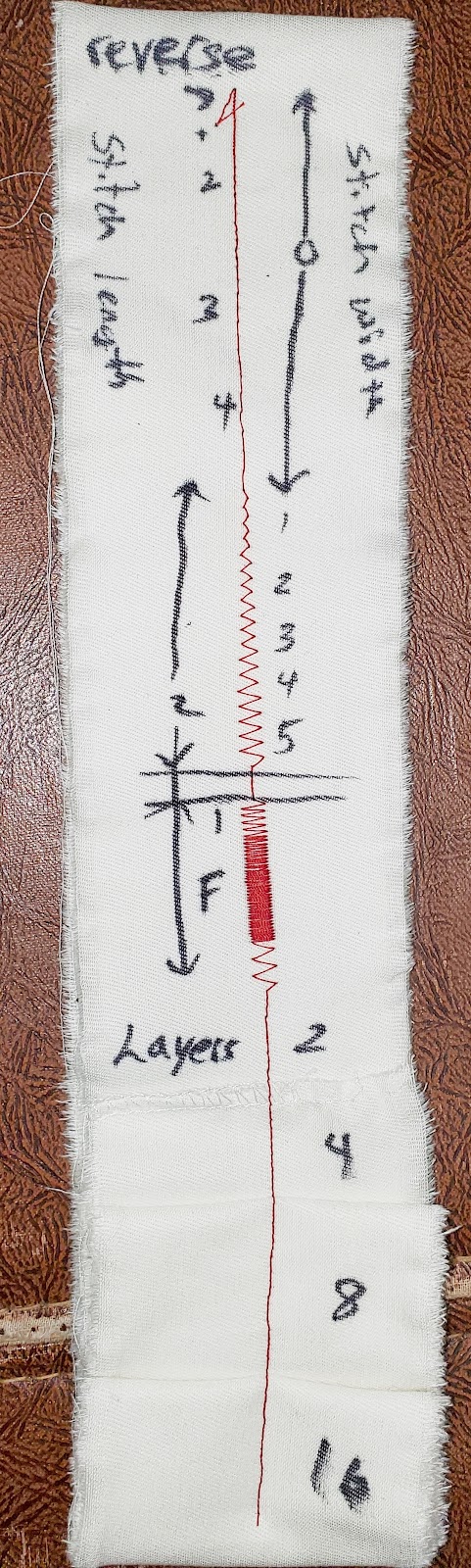

See the photo above. Each separate line of stitching shows some attempt. First, trying each number on the tension dial. Then the in-and-out tinkering including entirely dis-assembling and re-assembling it. Nothing changes.

Here's a closeup of the what ALL of the stitches looked like on the back of the work.

The photo above shows the bottom, or underneath side of the stitching. A problem that appears on the top is the result of a bottom tension problem. A problem on the bottom is a result of a problem with the top tensioner.

Spent a couple of hours on this. Went through my box of tensioners harvested from dead machines, but nothing fit.

Downgrading the gear and the tensioner to nylon and plastic was criminal manufacturing malpractice. Sadly unrecognized by our legal system. I'm not nearly as upset by the cheap crappy plastic machines being poured out by the millions today. Nobody should expect those to last. But this could have been a real treasure. Sigh.

I had adjusted the bobbin tension early in the testing process. I have a "feel" for what a decent bobbin tension is, and I went bit beyond it. After I had finally given up on the top tension I revisited the bobbin tension and loosened it up much more. I was finally able to get a decent result, but only on stitch length 2, or on thicker fabric layers.

When I have finished testing a machine I leave the test sample with it.

And I write on it with a sharpie so the recipient will understand how it was tested and what the results were.

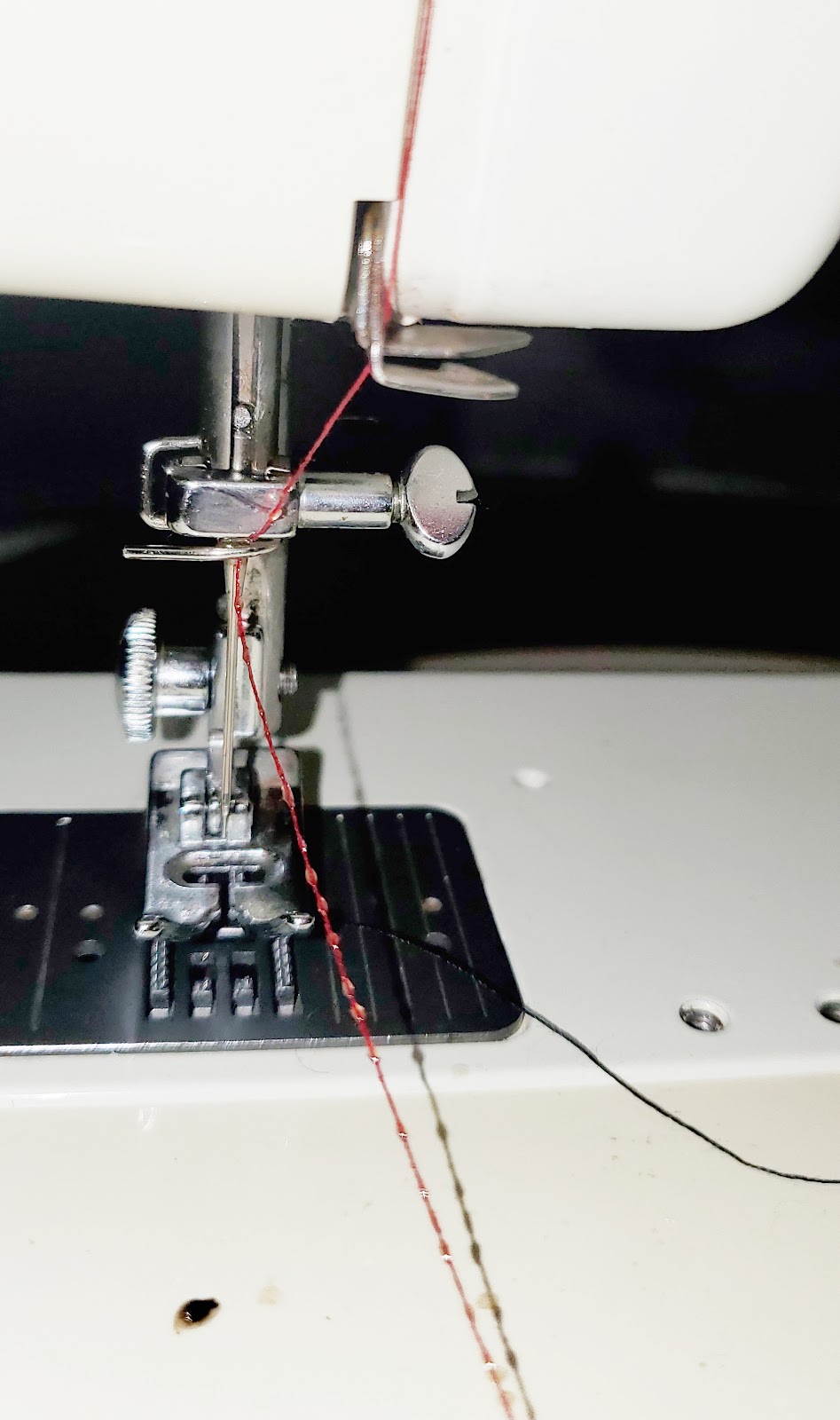

It's a basic zigzagger with slot threading and a free arm, the absolutely perfect type of machine for the occasional seamster. Slot threading is shown in the photos, and replaced the little metal guides along the thread path. On the older style machine you have to guide the thread through each one. On a slot thread machine the thread just glides into the slots.

(and I'm sorry I didn't take a picture of the free arm. Too late now, it is packed up.)

Slot threading is just about the only modern "improvement" I actually enthusiastically endorse. So quick and easy. And since we've been talking about tensioners, let me vent for a minute. The absolutely best tensioners, hands down, were the leaf tensioners on machines from the 1880's. Simple. Easy to use. Dead easy to understand.

Here's a Domestic High Arm Fiddlebase from around 1880. The leaf tensioner is on the top of the arm of the machine.

And here's a closeup of the tensioner.

I'm a charter member of the Leaf Tensioners Fan Club. The other members are Missie and Linda. We even have t-shirts. No kidding. I'd show you a photo but I would first need permission to republish the original art work on the shirts. And I'm not sure who holds the copyright. (Feel free to chime in and tell me, Missie).

Photo above shows how incredibly complicated a leaf tensioner is not. Two strips of metal with a screw you can tighten or loosen to control the tension. (The photo was taken before I cleaned it up btw).

My hypothesis is that sewing machine manufacturers respond to complaints from customers by trying to "improve" things and almost always make things worse. Tensioners are the perfect example of this. Modern machines are designed with the tensioners hidden inside, and its not possible for the owner to open the casing. So a thread caught in the tensioner means a trip to the repair shop.

Hannah recently had such a problem and she was quoted $100 as the base price for bringing it in. Her "modern" (circa the 1990's) top-of-the-line Pfaff would only sew for a few inches before the thread would break. Fortunately we were able to diagnose the problem and I got most of the thread caught inside the tensioner with long skinny tweezers such as those that come with a serger. That thread broke, leaving some inside the machine, and I thought that was the end. But the little piece left in there came out when we tried stitching again. Whew! Problem solved.

Bobbins are another example of a "improvements" that don't. Leading ultimately to the most heinous bobbins ever created, the ones on the Singer Touch N Sews. People complained (and still do) about bobbins running out of thread. So Singer had the bright idea of winding the bobbins while still in position below the needle. Those bobbins held even less thread than a regular bobbin and the system was plagued with problems. (This is my own opinion, based on painful personal experience. And now is a great time to remind you that, as I have often stated, I AM NO EXPERT. Just a person with a blog. Not the same thing at all.)

Fortunately most of the modern machines I see now (and I don't see many) use class 15 bobbins. They may drop in the top as the Singer class 66 ones used to do, rather than go in a removeable bobbin case. But they are class 15 bobbins.

Not everyone hates Touch N Sew machines of course. At a recent Repair Cafe (look it up, I plan to blog about it later) we had a 90 year old client who brought one in. She had bought it new in the 1970s and had used it ever since. Made curtains, clothes for her children and grandchildren, etc. She loved it. I don't remember what the problem was, but she said she had taken it to be repaired three times and the problem always returned. I had to tell her that if professional repairs had failed three times it was unlikely that I (not an expert) would be able to fix it and that she should value the memories and realize that it had lived a long and useful life and was probably just done. She took the news well.

So, what am I going to do with this Brother VX-808? It does sew and the stitches are secure. Stitch width and length all work properly. It was frozen when I got it but just from sitting for decades while the oil dried and hardened. There was some rust on the needle bar, which I sanded off with 400 grit sandpaper. It was rust free and lint free inside. It's now serviced and running smoothly.

Usually if I can't fix a machine I cannibalize it. But this one is functioning, and it might serve someone for a long time. With slightly wonky tension. And until that nylon gear goes out.

I can't take any money for it. But I was recently told about people who know how to sew and are in need, and in need of some sewing machines. I'm going to include this one in the group of machines I am taking to them. I wouldn't palm this off on a newbie, but an experienced seamster, displaced from their country, with enough knowledge to know what is going on, may get some use out of it.

Best I can think of to do anyway. What would you do? Please tell me in the comments below.

* * * * * * * * * * *

If you are still here after my long absence, drop a comment to say "hi". I guarantee it will thrill me to hear from you!